When tech innovator Dave Keicher requested marketing and sales growth services from New Mexico Manufacturing Extension Partnership (New Mexico MEP), the nonprofit organization saw it as an opportunity to experiment. New Mexico MEP helps manufacturers increase their competitiveness and profitability by improving processes.

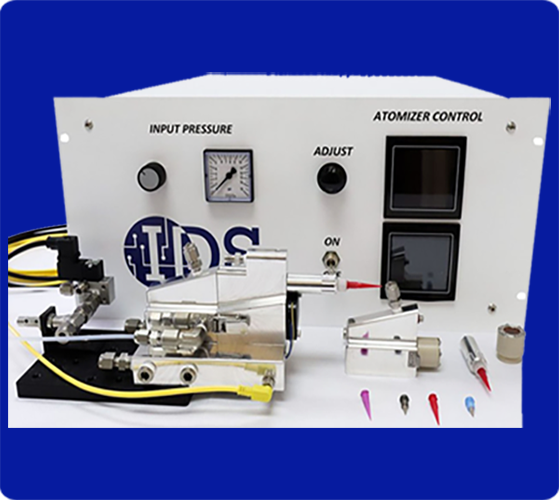

Keicher is vice president of Integrated Deposition Solutions (IDS), whose founder Marcelino Essien patented an aerosol printing technology that IDS calls NanoJet. Keicher helped develop the technology at Sandia National Laboratories and was an early investor in IDS.

The request from Keicher revealed a gap in the services that New Mexico MEP typically provides. Rather than relying strictly on its own Innovation Directors, New Mexico MEP contracted with “resource partners” to supplement its services.

Sara Douglas is a New Mexico MEP staff member who also owns an executive coaching firm that got its start at the BioScience Center business incubator in Albuquerque. It was there that Douglas met Essien, who was launching IDS at about the same time. Douglas said relationships grew among the tenants.

Douglas also found camaraderie with another BioScience Center tenant, Lynore Abbott, CEO of Logical Marketing. “We were just starting our businesses, and we helped each other,” Douglas recalled.

IDS spent its first few years at the incubator developing its patented printed-electronics technology. “We started working in 3D printing several decades ago, before anybody knew about 3D printing,” Keicher said about the genesis of the company. “Printed electronics can change the way industry manufactures stuff, like 3D printing did” by making it possible to create or embed tiny components that can replace outmoded machine parts without requiring a complete retooling of the machine. “If you actually embed electronics while you’re printing a 3D part, that provides the functionality,” he said.

Keicher approached New Mexico MEP when IDS received a significant investment that could help it grow.

Pilot project

Keicher said New Mexico MEP’s Douglas created a framework for the assistance IDS would receive. “Initially we did some team-building exercises that helped us figure out how to deal with each other better,” he said. “From there we added the infrastructure to manage our growth from a sales and marketing perspective.”

Douglas brought in Abbott to analyze markets and review IDS sales processes; and under Abbott’s direction, the company implemented a customer relationship management (CRM) system to help it manage the increase in order volume. Douglas and Abbott led the IDS team as it adjusted processes and improved standardization of products; and the two consultants worked individually and in sync to address specific issues as they arose. When IT and other challenges emerged that were beyond their expertise, other professionals were recruited to address them.

In the year since the pilot began, IDS has moved from a 1,200-square-foot space at the BioScience Center to a new 6,000-square-foot facility in northeast Albuquerque. Sales are growing, as is the work force. “In 2018 we did about $100,000 to $200,000 in revenue,” Keicher said. “Last year we did $1.1 million in revenue, and our goal this year is $3 million. I can’t tell you how much we appreciate New Mexico MEP.”

Learn more about New Mexico MEP and Integrated Deposition Solutions (IDS).

Finance New Mexico article 714.