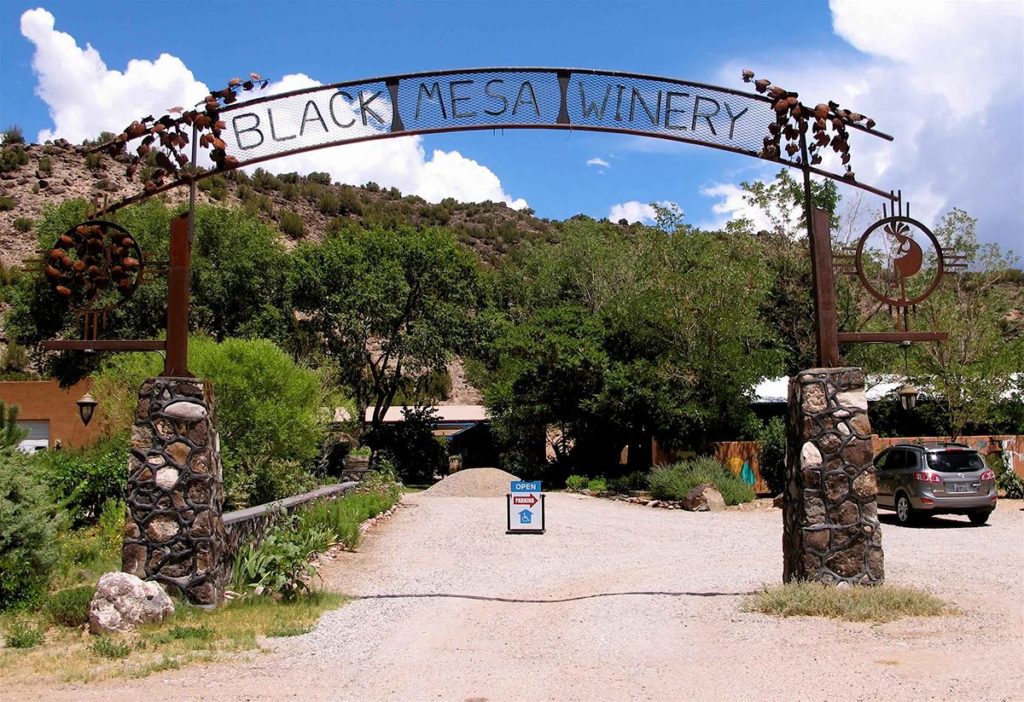

When the coronavirus pandemic temporarily halted tourist traffic and shuttered restaurants and bars throughout New Mexico, Black Mesa Winery in Velarde had an inventory of wine and hard cider worth $100,000 and fewer avenues to deliver its products to customers. Winery owners Jerry and Lynda Burd were able to keep products moving out the door through online wine tasting events, shipments to wine club members, and creative drive-by tours that kept customers engaged.

The slowdown also gave the Burds time to examine all aspects of their operation and to consider changes that could streamline processes, open new markets, and increase market share when the pandemic ended.

The Burds sought help from New Mexico Manufacturing Extension Partnership (New Mexico MEP), a nonprofit organization that helps businesses transform their operations to improve production, competitiveness, and profitability. New Mexico MEP Innovation Director Scott Bryant worked with the couple and their 12 employees to help them evaluate the entire production line.

Bryant broke down each step involved in producing Black Mesa Winery’s 30 different wines and four flavors of cider. He identified how the winery could improve material handling safety, simplify some aspects of production, and adopt new manufacturing technologies appropriate to its capacity and volume.

To improve efficiency, Bryant suggested shortening the distance between production and shipping operations to minimize the time spent filling orders. He also urged the Burds to close the gaps between different production processes by adding wheels to equipment that is used at multiple places on the property. This modification, which could be done by a local machinist or welder, would allow equipment to be moved as needed around a dedicated space in the facility that is closer to the storage tanks.

“What Scott challenged us to do is question how do you make this happen more quickly, how do you make the process flow,” said Jerry. “You make the wine flow through a hose; you don’t move the tanks. You make the cider flow from beginning to end in one building. He helped us to see how a minute here and a minute there adds up to a lot in a year.”

The evaluation process allowed the winery to retain 3 otherwise idle employees and identified small changes that resulted in cost savings of $50,000 — a large number for a small business during a pandemic.

“We’re not working any longer hours and we’re not working harder,” Jerry said. “We are getting more done.”

The seeds New Mexico MEP planted are now part of a continuous process of improvement at the winery. Some of Bryant’s advice remains posted on a wall. When questions arise, Jerry replies, “Remember what Scott said,” as he points to the wall.

The Burds are also testing a new technology packaging system they learned about from Bryant. If their experiments deliver positive results, customers will be delighted and the winery will save costs related to transportation, shipping, and cleaning. The change could increase market share and help the winery expand into new markets.

“The same old, same old, was not going to work, and you want to come out of this being able to hit the ground running,” Jerry said.

Black Mesa Winery has emerged from the pandemic stronger than before. Sales in 2021 are ahead of 2019, and cider production has more than doubled. As the only cidery using 100 percent New Mexico-grown apples, sourced from Taos to Espanola, Black Mesa Winery is also helping develop the rural economy.

Get more information about New Mexico MEP and learn more about Black Mesa Winery.

Finance New Mexico article number 723.