Matt Moser, Innovation Director, NM Manufacturing Extension Partnership

Most entrepreneurs who approach the New Mexico Manufacturing Extension Partnership are well along in production of an invention or commodity. Some operate decades-old businesses but need help identifying and overcoming production bottlenecks and instituting lean processes that can increase their profitability and competitiveness.

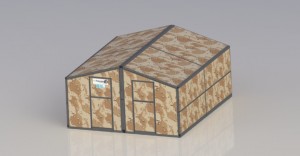

Vince DiGregory tapped into the talent at MEP before he had even built a prototype for the folding flat-pack modules he hopes will revolutionize the temporary shelter industry for military and disaster relief operations.

DiGregory’s invention is an 8-by-8-foot folding structure that can interlock with other modules to create larger enclosures. The lightweight structure can be rapidly assembled and taken apart, making it ideal for small-scale, temporary operations.

4-Unit

DiGregory began working on his idea about 10 years ago when he worked as a general construction contractor in Albuquerque. After qualifying for technical assistance through the New Mexico Small Business Assistance program, he collaborated with Sandia National Laboratory professionals on the design and structural testing of his product.

A Wealth of Resources

DiGregory retired from construction in 2010 to pursue his venture full time. He applied for a patent with help from Technology Ventures Corporation and he approached MEP for help planning the layout of his production line so he could determine how much each module would cost to build.

By then, DiGregory was far enough along on his invention to qualify for help from MEP — just at the cusp of the late concept and early manufacturing stages. And he had the required state tax ID number and a Dunn & Bradstreet Research and Development profile and manufacturing code profile from the North American Industry Classification System.

Single Unit Flat

About 18 months ago, he teamed up with MEP to work on plant design and production forecasts. Under MEP guidance, he used a lean-manufacturing technique called value stream mapping to create a visual map of how the panels could be produced with optimum efficiency. The process usually applies to existing production lines, detailing the route from raw material to finished product and comparing it with an idealized map free of waste and redundancy. The goal of value stream mapping is to work toward the stripped-down ideal so products can more quickly get to consumers.

In this case, he worked from scratch to hand-design a production line that could manufacture 90 units every eight hours.

3-Unit

A $40,000 Department of Energy grant is funding Sandia National Laboratory engineers to help DiGregory develop radar, electromagnetic and thermal control systems into the panels of his structures – even as he pitches his product to the military and plans to market it to disaster relief agencies and industries.

DiGregory took advantage of numerous business resources to reach this point, but without MEP’s help, he said, “I would have had to spend tens of thousands of dollars to get to this point.”

Download 280_ MEP Helps Entrepreneur Prepare Revolutionary Product PDF